About Us

We are a group of aviation enthusiasts from our "Science and Technical Communication" class. We were asked to evaluate aviation blogs and find a blog that inspired us to create our own.

This is our take on an aviation blog, specifically about aviation technology. Each blog is written by one of us to inform our audience of new innovations in aviation. At the bottom of our blog is a vlog consisting of a view during our "Panther Flight Fest" school event.

Aviation technology is a very broad field of the aviation industry; this could include new planes, wings, drone designs, and changes in cockpits or engines.

We wanted to go deeper into the different sections of aviation technology. Scroll down to read our blogs and watch our vlog!

Blogs

By: Sabrina Ott

04-11-2023

The aviation world has been slow regarding new technology; it takes many years to see improvements or changes in the aviation industry. But, automation has become a huge part of the industry, especially with autopilot. This is a big improvement, especially regarding longer flight durations; it minimizes the chances of human error and keeps the pilot attentive to the surroundings. However, automation has negatives, such as the talk of reducing the number of pilots in the cockpit. This could be from a captain and copilot (2 people in the cockpit) to just a captain, a first officer (copilot), or no pilots in the cockpit.

There has been a huge pushback from pilots to this situation due to the safety of this situation. While it is an incredible addition, automation is not always perfect, and having no pilots or a single pilot in the cockpit can lead to unsafe situations in the plane. Not only have pilots given pushback, but so have the people. Studies have shown that 81% of the people researched are uncomfortable with flying in an airplane with a single or no pilot. The biggest example of the positives of having a two-person crew is the Hudson River situation with Sully. This blog includes Sully and his reasons why aviation should not eliminate pilots. Sully specifically states that having a minimum of two experienced and trained pilots was the reason he could save the people on board when he was in an emergency.

Click on the title and picture to learn more about this topic!

By: Aidan Pryzgoda

04-12-2023

Ammonia could be the world's new hope for a carbon-neutral aircraft flight. A U.K. government startup known as the Reaction Engines and U.K. Research and Innovation’s Science and Technology Facilities Council (STFC). has a prototype fuel that is a mixture of hydrogen and ammonia. This prototype burns just like conventional jet fuel and matches the stability of modern jet fuel. The world is already set up to manufacture a very large amount of ammonia every year due to the world's demand for it in fertilizers. Since the process for making ammonia is already established worldwide, it would be more feasible to integrate it into airplanes sooner rather than later.

In a press statement given by Reaction Engines, “The density of liquid ammonia allows for conventional aircraft configurations to be used, and it may be possible to retrofit into an existing engine, resulting in a zero-carbon jet that could start serving the short-haul market well before the 2050 target currently set by the industry.”

There are, however, a few limitations currently in the way of this conversion. Ammonia is very toxic and is a vapor in most conditions. This makes it an inhalation risk for any workers handling it. To try to fix this, ammonia is commonly transported in pressurized train tanks that keep it in its liquid state. This is great until you consider the engineering challenges of pressurizing the airplane's fuel storage systems.

While ammonia may be promising as a future fuel source, some argue that it is not necessary for lowering the CO2 content of the atmosphere. The most sensible solution may be to continue the development of ground systems that pull CO2 from the atmosphere and not mess too much with the aircraft due to all the technical challenges that arise from keeping a giant piece of aluminum and people in the air.

Click on the title and picture to learn more about this topic!

04-14-2023

By: Jaein Choi

An economical automatic refueling system is under development to prevent manpower loss. This technology will prevent the loss of manpower caused by refueling the aircraft. After the aircraft stops, the system opens the flap, unlocks the cap, lifts the fuel nozzle, inserts it into the tank opening, and automatically leads to fuel injection. These automation technologies eliminate the human error and loss associated with manual measurement and adjustment of fuel inventories in fuel tanks and traditional paper issuance for fuel trading in aviation fuel supplies. Simplify the complete fuel ecosystem for both commercial and general aviation. Several steps are needed for technology for automatic refueling.

1. Capture fuel transaction data with EMR4 electronic meter register

EMR4 is an approved electronic meter register for commercial use and shall be designed to be installed or integrated into all meters. With a series of accessories, the core components require the user to configure a system that meets specific requirements from aircraft refueling machines, fire hydrant carts, fuel farms, or wherever fuel is supplied from the airport.

2. Automate data transmission by integrating DATALINK with EMR4

For fully automated wireless solutions, EMR4 must be paired with Datalink software. This process eliminates manual ticketing, eliminating lost, missing, and miswritten tickets and relocating people to more productive business operations areas.

3. Remove manual measurement of fuel inventory with TLS4I or TLS4C automatic tank gauge

The TLS4I/TLS4C automatic tank gauge system is an easy-to-explore process that reasonably simplifies wet inventory management.

Click on the title to learn more about this topic!

By: Junho Lee

04-14-2023

The aviation industry has consistently noted the same thing from the past to the present. It is whether making the maximum profit at the minimum cost. Operating aircraft requires a lot and various expenses, and fuel is one of the biggest portions of total expenses.

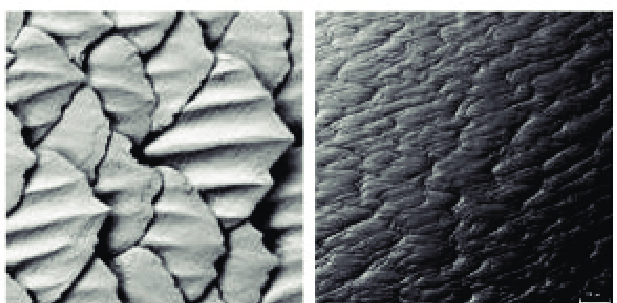

The aviation industry has been trying to increase fuel efficiency and decrease drag, increasing fuel consumption. Therefore, Lufthansa airline device AeroSHARK films can easily attach to the airplane surface. The modifications to the aircraft skins will allow an airplane to have less parasite drag (skin friction drag), which means the airplane will burn less fuel. The film was developed to mimic the skin of sharks. Sharks travel very fast in the water. Because both water and air are fluids, they are based on hydrodynamics. Therefore, the shark’s rapid and smooth movement was applied to the aircraft.

The good thing about films is that they are simple and efficient. Aircraft have mostly changed the entire frame and engine to reduce fuel consumption. However, the aeroSHARK riblet film is simply attached to the aircraft fuselage. It can reduce 1% of skin fraction and 1% CO2 emission. It sounds small, but in terms of long-term perspective, these simple films will save more than 1,200 tons of CO2. Lufthansa Group estimates they can reduce more than 25,00 tons of carbon footprint per year by using these films.

Click on the title to learn more about this topic!

By: Bonhyeok Koo

04-14-2023

Since electric propulsion systems with hydrogen cells do not emit carbon dioxide, they are considered the most promising alternative energy to reduce or eliminate air pollution caused by aviation. The development of an engine that uses environmentally friendly alternative energy from existing fossil fuels that emit carbon dioxide is expected to be accelerated by Airbus' ZEROe (Zero emission) project. ZEROe is one of Airbus' biggest projects to develop the world's first hydrogen-powered commercial aircraft by 2035.

Hydrogen can be used as an energy source for aircraft engines in two ways. First, aircraft can get energy from burning hydrogen in a gas turbine. Water is the only by-product in this process, so it does not cause environmental pollution. The second is to make a fuel cell using hydrogen and to supply electricity to aircraft engines. Airbus is trying to create a battery-free hybrid engine, a technology that combines these two methods.

“The electricity generated by the propulsion system proposed by Airbus happens through an electrochemical reaction between hydrogen and dioxygen molecules in the fuel cell. The resulting action produces a direct electric current, which is converted into alternating current, which powers the propeller motor and provides the thrust. As an “emission”, this type of engine expels the water into the atmosphere” (Vinholes, 2022)

The hybrid engine will be tested to accommodate 100 passengers aircraft with a range of around 1000 nautical miles on an aircraft based on the A380, one of Airbus' models.

Click on the title to learn more about this topic!